DAEWOO tipper trucks Gr.D22-SH-II

Specifications

- Geometric volume

- ≈ 22 куб.м.

- Maximum body lift angle

- 48 - 50º

- Permissible gross weight

- 43 000 kg

- Loading height

- 3 100 mm

- Base chassis

- Daewoo CR8M7-NOVUS

- Body internal dimensions, mm (length x width x height)

- 6 590 x 2 450 x 1 665 mm

- Hydrofication

- Binotto / HYVA

- Vehicle wheel base

- 8x4

- Body

- half-pipe

- Transported cargo weight, kg

- 27 050 kg

- Subframe material

- S500 MC construction steel

- Body material

- wear-resistant steel

- Lateral side thickness

- 5/6 mm

- Body base thickness

- 6/8 mm

- Model name

- Gr.D22-SH-II

Description

Grunwald presents the Daewoo Novus tipper truck with the Grunwald tipper superstructure. The vehicle is capable to tackle any challenges in construction and redevelopment work with confidence. This Korean “dragon” is a genuine trusty worker!

The Gr.D22-SH-II tipper superstructure is the paragon of further development of Grunwald bodybuilding program for the Russian market. This product has the potential to challenge the stereotypes that have long been established in Russia regarding the optimal body shape for a tipper truck.

- Ladder in the front part of the body with a mating structure for steps;

- Spare wheel bracket on the body front wall;

- Removable protection screen made of steel;

- Body heating by means of exhaust gases;

- The body heating parts, including the three-way valve, are made of AISI 304 stainless steel;

- 200 and 250 bar hydraulic cylinders manufactured by HYVA or Binotto concern;

- A high capacity hydraulic pump.

Body heating system

Pipes and corrugations of the body heating system are made of AISI 304 stainless steel. The AISI 304 characteristic higher operating temperature and working pressure range ensures maximum service life of these elements.

Half-Pipe body

Half-pipe bodies have greater structural rigidity with less weight compared to "box-type" counterparts. There are less welds on the half-pipe body, and therefore fewer points of potential stress and corrosion. The half-pipe shape provides for better resistance to cargo building up on the inner corners of the body.

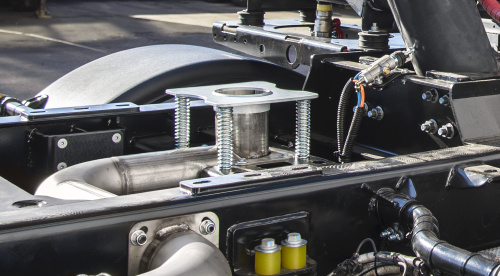

Hydraulic system

Hydraulic equipment reliable enough for operations under high loads is supplied directly from the leading European suppliers. High opening speed ensures fast unloading of the body.

- Additional hydraulic line equipment for work with trailers. Trailer body lifting hydraulic line, with features such as quick disconnect coupling and control from the cab;

- Lifting underride protection bar. Enables work with asphalt paver, while providing the maximum exit angle.

The semitrailer structure warranty period is 12 months from the date of initial registration, but not more than 24 months from the date of production.

Warranty and service obligations shall be fulfilled by a specialized Grunwald service center in Moscow (Sheremetyevo), as well as a network of authorized service stations.

Place an order for this model

Fill out the order form and our managers will contact you:

Hotline number:

8 (800) 444 65 39Use our financial instruments:

LeasingTrade-in your vehicles for new on favorable terms:

Trade-in