/

Specifications

- Geometric volume

- ≈ 22 куб.м.

- Maximum body lift angle

- 48 - 50º

- Permissible gross weight

- 50 000 kg

- Loading height

- 2 950 mm

- Base chassis

- SCANIA P440 B8x4HZ

- Body internal dimensions, mm (length x width x height)

- 6 100 x 2 450 x 1 500 mm

- Hydrofication

- Binotto / HYVA

- Vehicle wheel base

- 8x4

- Body

- box-type

- Transported cargo weight, kg

- 32 000 kg

- Subframe material

- DOMEX 500 MC construction steel

- Body material

- Wear-resistant HARDOX 450 steel

- Lateral side thickness

- 5 mm

- Body base thickness

- 8 mm

- Model name

- Gr.S22-SB-SI

Description

SCANIA XT vehicles with Grunwald superstructures can be used at all construction stages, from construction site preparation stage to the final landscape design.

In virtually all of their characteristics – from the power units efficiency and chassis performance to the high reliability of the tipper superstructure – SCANIA XT tippers show an exceptional level of efficiency that exceeds expectations.

The first SCANIA XT trucks with Grunwald tipper bodies were presented to the transport community in 2019. The vehicles received high praise for safety, technical equipment and performance – and thus opened the opportunity for the development of a strategically important partnership between Grunwald and Scania CV AB and the expansion of the range of joint projects.

-

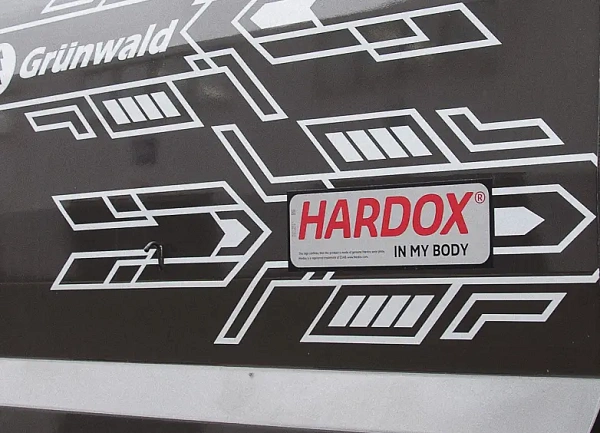

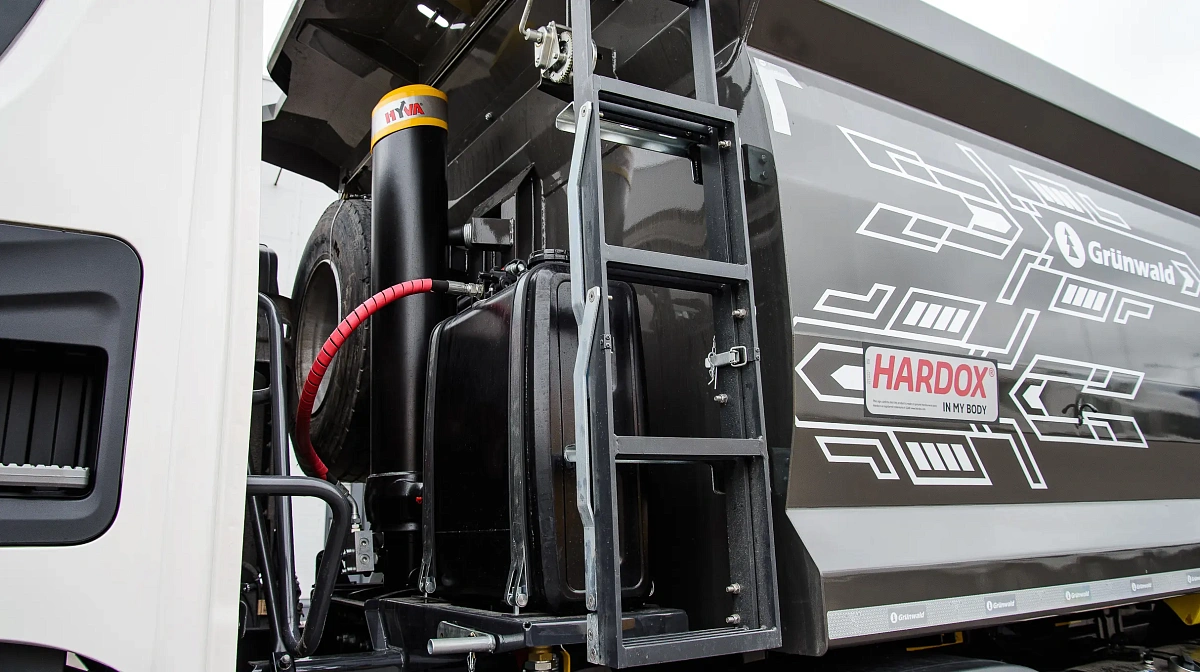

Steel body with rear-side unloading is made of wear-resistant Hardox 450 steel and certified according to the “Hardox in my body” program;

-

Ladder in the front part of the body with a mating structure for steps;

-

A bracket for a spare wheel on the body front wall;

-

Removable protection screen made of steel;

-

Removable delivery chute;

-

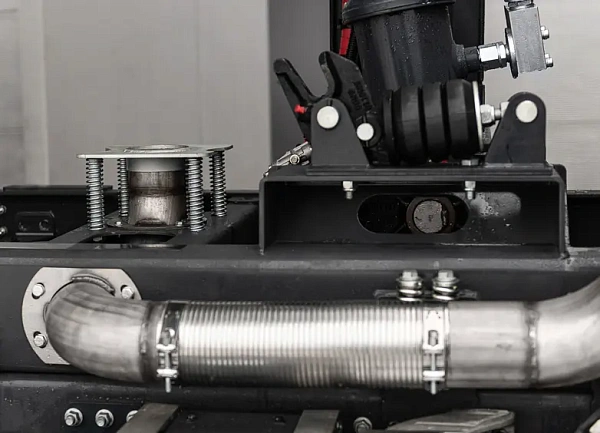

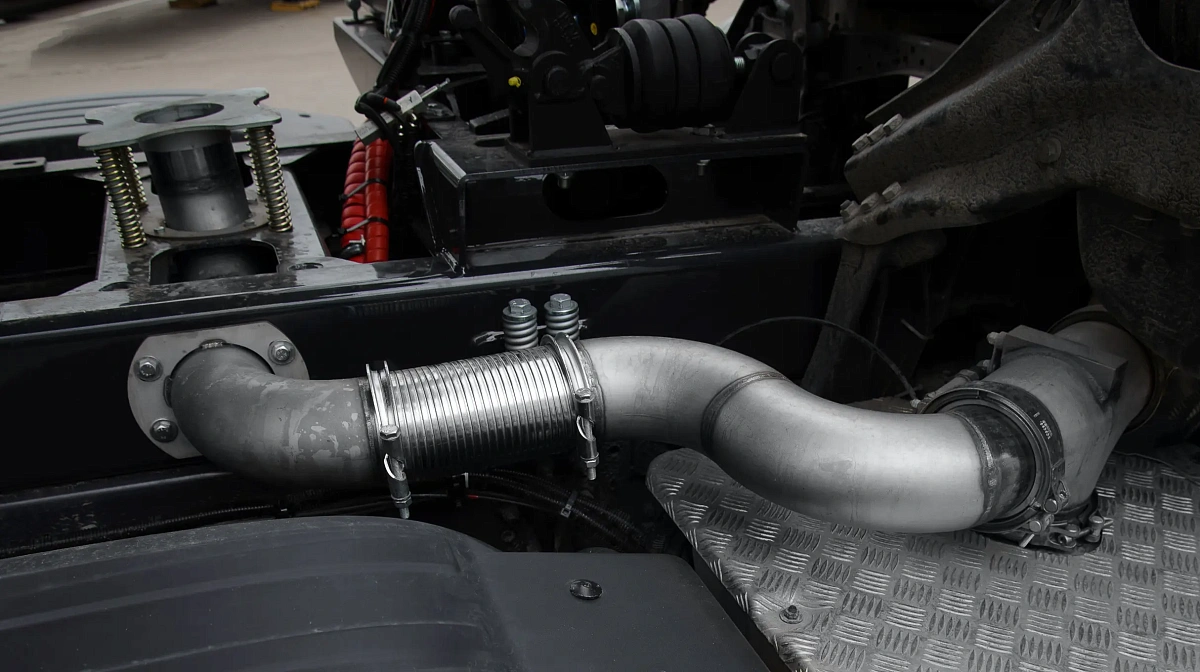

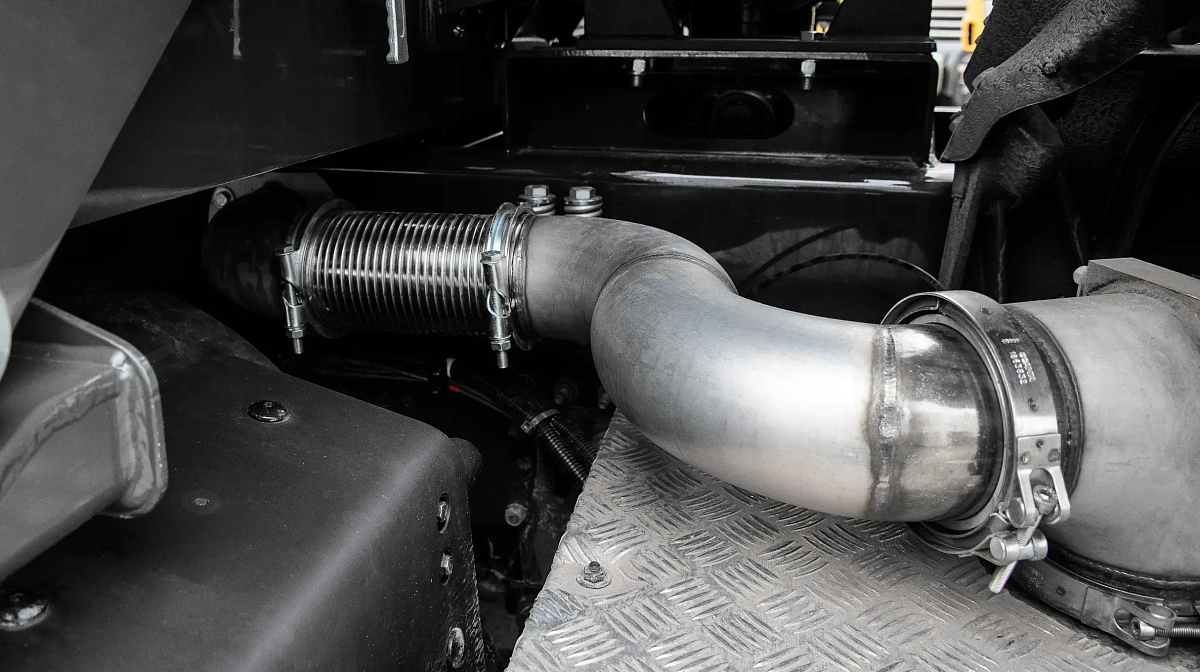

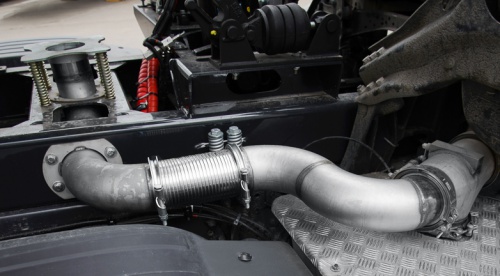

Body heating by means of exhaust gases;

-

The body heating parts, including the three-way valve, are made of AISI 304 stainless steel;

-

Low pressure 200 bar hydraulic cylinders manufactured by HYVA or Binotto concern;

-

A high capacity hydraulic pump.

Advanced components

The hydraulic equipment is supplied directly from the leading European manufacturers and is highly reliable. High opening speed ensures fast unloading of the body

Body heating system

The Gr.S22-SB-SS superstructure is equipped with an attachable body heating system. Branch pipes and corrugated pipe of the body heating system are made of АISI 304 stainless steel. Increased high temperature and operating pressure range characteristic of АISI 304 steel ensures the maximum service life for these elemen

Advanced materials

The design of Gr.S22-SB-SS superstructure asserts the company’s principle of using the best materials and components available on the market. This is the reason for choosing the wear-resistant and shockproof Hardox 450 steel for body material. The “Hardox In My Body™” certification symbols on the superstructure sides confirm that the body is an outstanding product characterized by unparalleled wear-resistance and shock capacity

At the request of the customer, the semitrailer delivery package may be upgraded to include the following additional options:

-

HYVA SMART monitoring system with a tablet. It provides for monitoring the tipper truck operation – cargo weight, tilting angle control, control of the number of body tipping cycles, cloud service, etc;

-

Equipment of the hydraulic line for operations with a trailer. A hydraulic line for tipping of the trailer body, with a quick release joint and control from the cabin

-

Collapsible underride protection bar. Allows operations with asphalt pavers and ensures the maximum angle of departure;

-

Body base made of Hardox 500 Tuf steel. Wear resistance improved by 30 % as compared to Hardox 450 steel..

Warranty

The warranty period for the semitrailer structure shall be the lesser of 12 months from the time of initial registration or 24 months from the time of manufacture.

Applicable warranty and servicing obligations shall be fulfilled by a specialized Grunwald service center in Moscow (Sheremetyevo) or by any service station which is a member of Grunwald’s authorized service network.

Place an order for this model

Fill out the order form and our managers will contact you:

Hotline number:

8 (800) 444 65 39Use our financial instruments and get an interest-free loan:

LeasingTake advantage of the Trade-in program on favorable terms:

Trade-in